The Smarter Way to Prevent Drain Blockages

The Drain-Tech Automatic Grease Interceptor is an innovative, fully automatic system designed to efficiently separate and remove grease, oils, and food solids from wastewater before they cause blockages or odours. Engineered for durability and precision, it operates continuously and autonomously, keeping your plumbing systems clean and compliant with environmental regulations.

Whether installed in a commercial kitchen, restaurant, or food processing facility, Drain-Tech offers a smarter, safer, and more sustainable approach to grease management.

How Drain-Tech Works

Drain-Tech combines advanced bacterial solutions with practical dosing methods to prevent FOG buildup in drains and grease traps. The system offers efficient, ongoing cleaning while reducing reliance on harsh chemicals and minimizing environmental impact.

- 360º Cleaning: 1.5kg block dispensed into kitchen drains

- Slow-Release Blocks: 5kg block for external lift stations.

- Bacteria Sachets: 20gm powder for daily dosing.

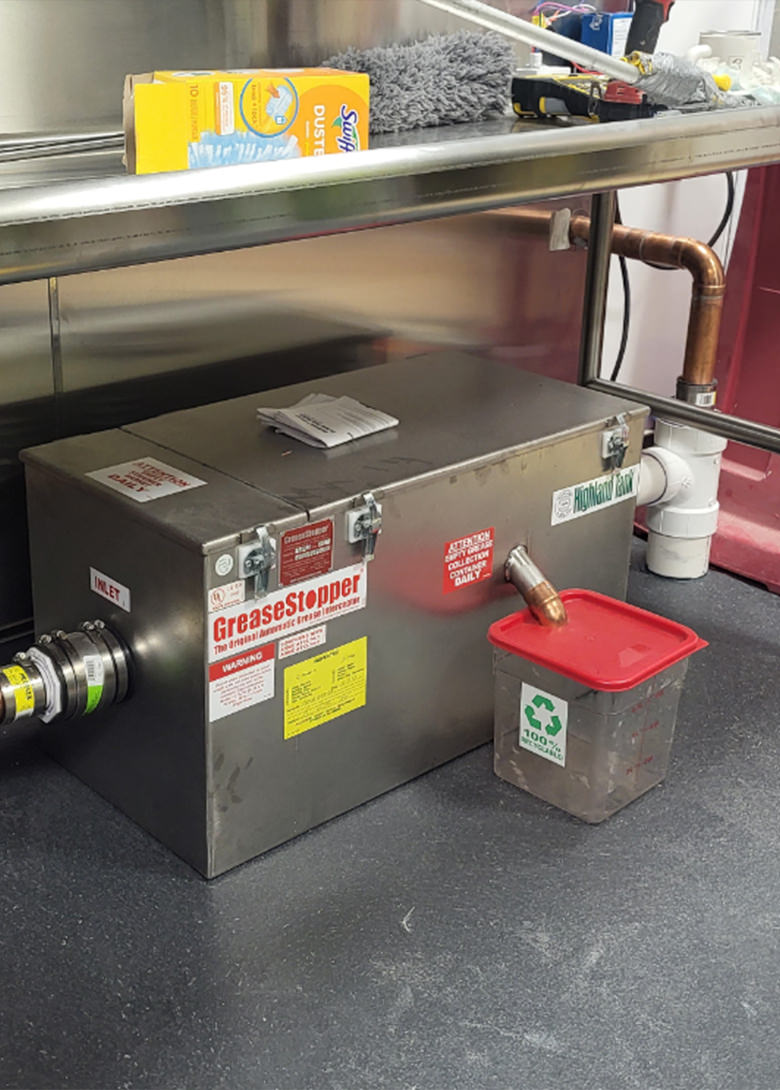

- Automatic Grease Interceptor (AGI): Captures oil and grease before drains.

- Commercial Sink Filter: Traps food debris effectively.

The Cost of Ignoring FOG

Untreated fats, oils, and grease (FOG) can quickly cause blocked lines and overflowing grease traps, leading to costly pump-outs and frequent maintenance. Left unchecked, this waste can disrupt operations and create unpleasant odours throughout your facility.

Beyond inconvenience, untreated waste poses serious health risks. Sewerage back-ups and sanitary sewer overflows (SSOs) are hazardous and expensive to clean up, while the property owner remains responsible for any damage or regulatory issues.

Typical Equipment & Bacterial Solutions

Grease Traps

Grease traps are essential for capturing fats, oils, and grease (FOG) before they enter the drainage system. By combining bacteria with a mild cleaning detergent introduced daily, the traps efficiently break down FOG, reduce odours, and help maintain free-flowing drains. This greener solution is safer for operators and the environment while keeping plumbing systems in top condition.

Lift Stations

Lift stations handle wastewater in larger or multi-level facilities, where untreated FOG can accumulate quickly. Using bacteria and detergent treatment in these stations ensures fats, oils, and grease are effectively broken down, preventing clogs and malodours. This sustainable method supports operational efficiency and reduces reliance on hazardous chemicals, providing a safer and environmentally friendly solution.

Advantages of a BioDose Block

Using a BioDose Block provides a more sustainable and cost-effective solution for managing fats, oils, and grease (FOG). It minimizes the use of hazardous chemicals, reduces single-use plastics, and is fully biodegradable. Each block treats extensive pipework efficiently, improving safety for operators while lowering transport and handling challenges.

With carefully selected bacteria, the BioDose Block accelerates FOG breakdown, reduces foul odours, and supports continuous, eco-friendly maintenance. EFSA-compliant and QPS-approved, it combines performance with environmental responsibility, delivering a greener solution for every facility.

From Pipe to Grease Trap to Lift Station

Once bacteria are released into the drainage system, they begin consuming the food source, growing exponentially and producing enzymes that accelerate the breakdown of fats, oils, and grease (FOG). A mild detergent supports the cleaning cycle, while additional bacterial and fungal packets work in synergy with the biofilm to treat even the crust above the waterline.

One BioDose Block can last 2–3 months, depending on conditions and dosing, providing continuous protection throughout the system. Key enzymes include lipase to break down fats, amylase for starches, cellulase for vegetable matter, and protease for protein-rich waste. The block’s 360° foam coating ensures full coverage of the pipework, enhancing bacterial activity and reducing lag time for a cleaner, safer, and more efficient drainage system.